Technology is the driving force behind improvements in all industries. From health to retail, energy and finances, mechanization has proved to be the engine behind many processes. However, one of the areas where this development is best noticed is in the field of food manufacturing. These breakthroughs have changed every aspect of the food processing chain, making the industry more efficient, boosting output rates and facilitating smoother streamlines. As technology develops, you can expect to see more incoming changes. So if you believe they are likely to influence how you run your business, you should brush up on your knowledge of the key innovations revolutionizing the industry as you’re reading this.

Artificial Intelligence

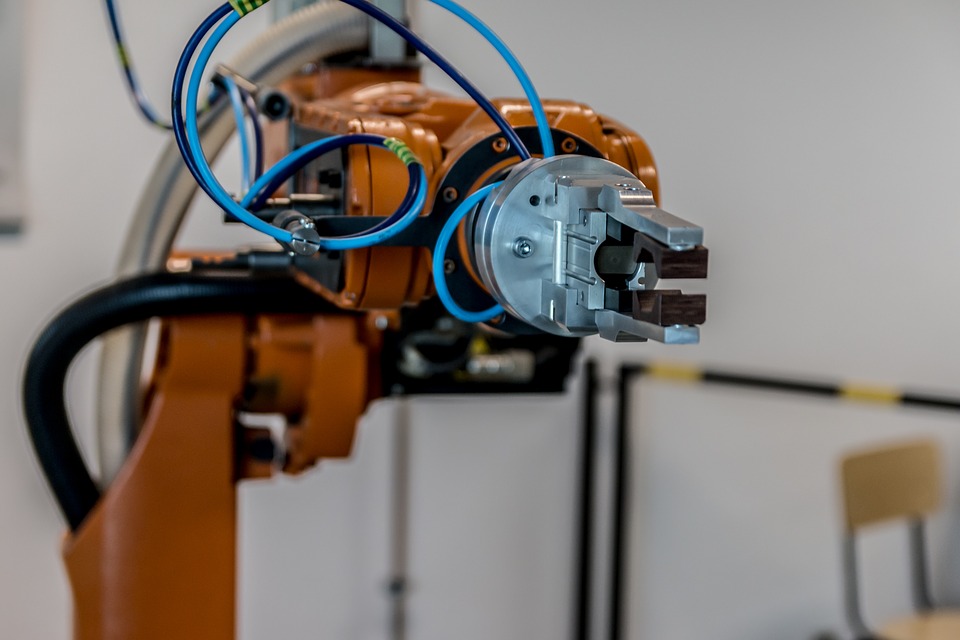

Often paired with the complementary field of advanced robotics, AI enjoys a wide range of uses in the food industry. When used concomitantly with existing machinery, it improves efficiency and production rates. This technology is beneficial for human workers, reducing some of the workload, monitoring quality more systematically, and helping improve the safety and general work conditions of employees. Cutting labor costs in the processing unit’s sorting and packaging is another way your company benefits from automation.

Some of the additional uses of artificial intelligence and robotics are sanitation, maintenance, and the handling of more difficult tasks holding an increased likelihood of injury for employees. Accurately assessing losses or inaccuracies in the production line, ranging from waste to color inconsistencies and differences in the sizes and shapes of the products, is more easily achievable with an expert system.

3D Printing

You’ve surely heard of 3D printing, the technological process of creating a three-dimensional item via a computer-based design. These objects are assembled layer-by-layer, gradually building the finished product. Food is the most delicious application of this tech advancement and certainly one of the most useful. There are different methods used in food 3D printing, including:

- Extrusion-based: This basic tech works by pushing foodstuffs via a mechanism using compressed air. Afterwards, the food can be baked, fried or boiled to facilitate consumption.

- Inkjet printing: Generally used for icing and decoration, this process adds edible food ink to food, usually deserts. Using a wide range of colors, it allows for the creation of a variety of customized designs.

- Binder jetting: Using food in a powdered form, this method layers dishes together with the help of a liquid binding solution. This technology is capable of creating a wide variety of shapes and textures.

- Bioprinting: A relatively new development, this is a more advanced form of food printing, which works by facilitating the replication of cells in order to create a dish. For example, you can recreate a steak using cattle cells and 3D bioprinting.

Specialized software

There are many types of software employed in the food manufacturing industry. Many fabrication processes are made more accessible via digitized programs. For example, deboning in the meat processing and packaging industry has been significantly simplified by the advent of the appropriate technologies which guarantee optimal yield per carcass. This is an integral part of avoiding waste and promoting sustainability within your business, issues of much debate and discourse. The efficiency of the automatized system also guarantees efficiency and can be easily integrated into already existing systems. The deboning stations are fully equipped and easy to clean and maintain, contributing to the optimization of logistics in your company.

According to DGS, as the complexity of sourcing and production chains is expanding, companies must seek to maintain up to standard and take all the necessary measures to ensure premium-quality products. Some of the solutions they offer include:

- ERP: This software can be tailored to individual processes and provides track and trace functions as well as periodical reports on your business. Monitoring stocks, purchases and sales becomes easy with the help of this tool.

- MES: A program that helps with the weighing, scanning and labeling of your products, as well as the management of orders, warehousing and recipes, it is valuable in maintaining optimal production parameters.

- PLC: Developed by expert software engineers, PLC helps with line and assembly maintenance, ensuring that your entire enterprise functions optimally.

Cellular agriculture

This technology has gained traction and become particularly well-known following the advent of cultured meats. The process includes the production of meat resulting from an in vitro process using animal cells. Ideally, the product is largely indistinguishable from traditional forms of meat, both visually and gustatorily. Lauded as an alternative that is more attuned to contemporary problems relating to the meat industry, such as the environmental impact and worldwide food security issues, this is a technologically-driven pursuit that may change the world for the better like few other scientific innovations before it.

The process, however, can be used on a variety of foodstuffs. Dairy is a popular area for development, with cheese being obtained from casein protein or yeast. Eggs, gelatin and coffee are other foodstuffs with which science has noted progress in synthetic derivation. The latter, for example, can be grown in bioreactors, which comes with decreased water usage and fewer carbon emissions.

Although this technology is still in its incipient phases, it holds considerable potential. It could ideally be used in the future to reduce issues such as food insecurity or diminish the effects of traditional agriculture on climate change.

Technological advancements are shaping people’s lives and businesses and societies everywhere, driving progress and optimizing traditional processes. There are many solutions making waves in the industry, ranging from production-helping tech to automatized delivery and making the processes of disposal, waste reduction, and recycling smarter and more efficient.

These changes work on all sides of the supply chain, from the farmers to the stores, helping speed up processes and overseeing the operations to safeguard the integrity and high quality of the produce. Technology is behind the increasing quality standard of foodstuffs easily observable everywhere, as well as for helping track potential food contamination outbreaks, which helps determine where the potentially hazardous goods have been shipped to know which niche of buyers to address.

With so many advantages, it is clear that technological upgrades in the food industry are only at the dawn of their existence, and the industry has yet to see the best of what they have to offer.