Robotics has been changing manufacturing technology for decades.

Production has advanced in numerous ways since the introduction of robots. Primarily, industrial robots can do repetitive tasks much more quickly than humans.

But today’s robots have become increasingly smarter, more autonomous, and more flexible, and they’re able to complete many tasks and make many decisions independently of human beings.

Rise of the Robots

Early industrial robots were mostly designed to perform sets of repetitive tasks in a highly controlled environment.

George Devol designed the first industrial robot in 1954, which was able to transfer objects from one point to another, over approximately a dozen feet.

Things progressed from thereon. In 1962, the first industrial robot to be used by a major manufacturer, Unimate, was installed by General Motors (News - Alert).

During the 1970s, robotics advanced much further. For instance, The Silver Arm robot, developed in 1974, was able to perform small-part assembly jobs by using touch and pressure sensors, and ASEA IRB, which was built in 1975, was the first fully-electrical driven robot and the first microprocessor-controlled robot.

And in 1979, Japan’s Nachi Robotics developed the first servo gun technology robot, used for spot welding, and OTC Japan introduced the first dedicated arc welding robots.

Today, robotic welding machines can automate the entire welding process by using machine vision and/or pre-programmed position.

Today’s Robots in the Manufacturing Industry

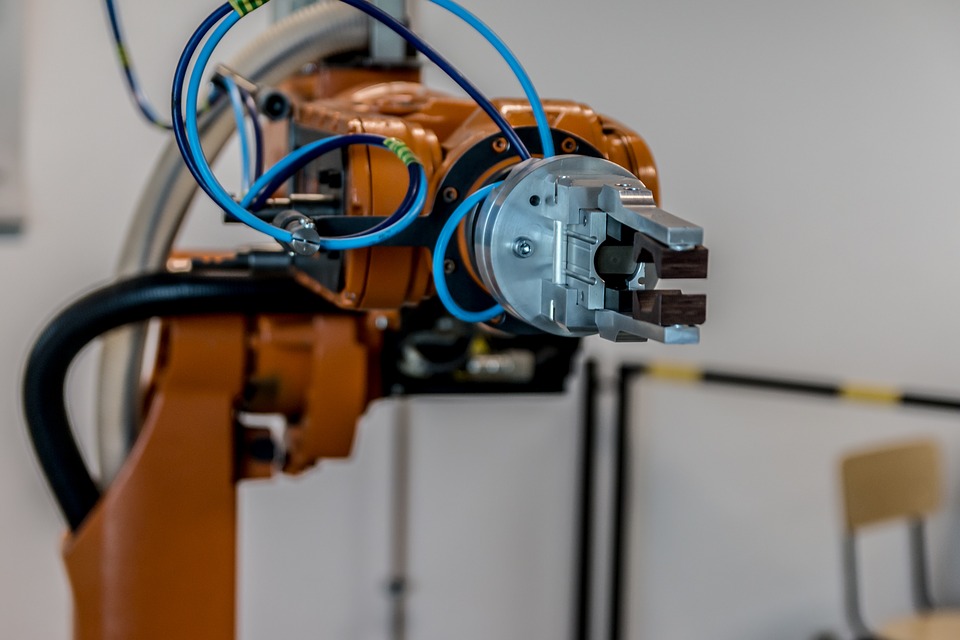

Various types of robots are now used for manufacturing, alongside robotic welding machines. One of the most well-known types is articulated robots.

Like CNC mills, articulated robots have multiple axes. Their dexterity, flexibility, and reach enable them to perform tasks like machine tending and they can easily reach under and around obstructions to gain access to workpieces.

Other common types of robots currently used for manufacturing include:

- SCARA robots, which can perform operations between two parallel planes, so they’re ideal for things like transferring parts from a tray to a conveyor and vertical assembly tasks like inserting pins.

- Delta robots, also known as spider robots, which use base-mounted motors to put their control arms into action, enabling them to make rapid movements, so they’re perfect for very high-speed operations that involve light loads.

- Cartesian robots, which usually have three or more linear actuators to fit specific applications and can be elevated in order to maximize the amount of floor space and accommodate a broad range of workpiece sizes.

Robotics Trends in the Manufacturing Industry

Approximately 2.7 million robots now operate in factories around the world.

By gaining a better understanding of the current trends driving robotics, we can get a glimpse of what the manufacturing technology of the future will look like.

Cobots

Cobots are robots that workers can interact with in a more effective way. They also make factories safer.

For instance, Comau’s Racer-5 cobot works accurately and quickly in tight spaces and can switch from industrial production mode to collaborative mode whenever a human operator approaches it.

Collaborative Robots

Open production lines don’t need access barriers anymore, thanks to collaborative robots that can optimize industrial layouts.

One type of collaborative robot is the automatic guided vehicle, which helps to ensure the smart control of intra-logistic flows, such as the Comau Agile1500, which is a fully-automated mobile robot that can optimize all sorts of logistic flows.

Smart Factories

The latest generation of robots aren’t only easy to program and install. They’re also able to communicate with other production lines and with central cloud-connected supervision systems, thanks to advanced sensors like vision systems and IoT systems that gather and process data.

Together with artificial intelligence, which enables robots to have advanced analytical capabilities and humanlike functionality to improve performance and accuracy, tomorrow’s robots will seamlessly work together to create entire smart factories.