TMCnet News

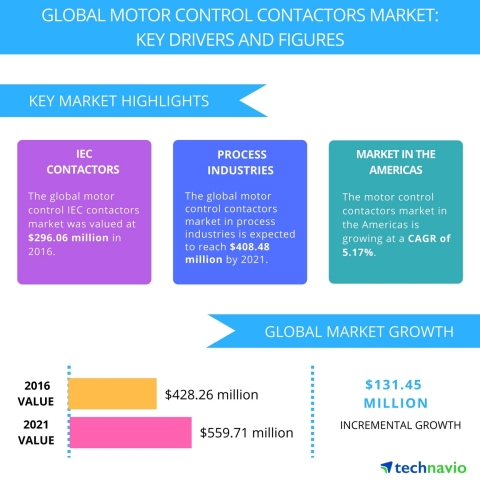

Motor Control Contactors Market - Drivers and Forecasts by TechnavioTechnavio analysts forecast the global motor control contactors market to grow at a CAGR of almost 6% during the forecast period, according to their latest report. This press release features multimedia. View the full release here: http://www.businesswire.com/news/home/20171115005897/en/

Technavio has published a new report on the global motor control contactors market from 2017-2021. (Graphic: Business Wire) The research study covers the present scenario and growth prospects of the global motor control contactors market for 2017-2021. Motor control contactors are electromechanical relays used for switching a large amount of electrical power in industrial motors. The contactors typically protect electric motors from high voltage and current fluctuations and ensure optimal performance in heavy duty industrial applications. Contactors are controlling devices that usually handle the heavy load of an electric motor. They are used for switching loads and are controlled by a circuit of much less power. They vary in size related to the power range dealt by the motor. They have ratings ranging from a breaking current of few amperes to a thousand ampere, depending on the motor that is connected to provide the protection. However, they are used for switching purposes and do not interrupt any short circuits like a circuit breaker. This report is available at a USD 1,000 discount for a limited time only: View market snapshot before purchasing Buy 1 Technavio report and get the second for 50% off. Buy 2 Technavio reports and get the third for free. Technavio analysts highlight the following three factors that are contributing to the growth of the global motor control contactors market:

Looking for more information on this maret? Request a free sample report Technavio's sample reports are free of charge and contain multiple sections of the report including the market size and forecast, drivers, challenges, trends, and more. Increasing use of smart control centers Smart control centers have the capability of measuring power and energy consumption precisely and are programmed to send a warning to the PLC and SCADA systems through an industrial communication network. If the system senses that power consumption is exceeding the pre-defined threshold, it immediately sends the warning to the controllers. Sushmit Chakraborty, a lead automation research analyst at Technavio, says, "The intelligent motor control centers are the filing cabinets of low-power-consuming starters, lighting contactors, and other electrical distributional and controlling products. They are gaining high popularity, as they allow short-circuit and overload protection, act as a power switching device, local and remote actuation, and provide controller state indication." Motor control contactors help in PFC (power factor correction) Major loads that draw electricity in the industries are inductive, especially in the case of motors. Inductive loads mainly need a magnetic field and two types of power to operate. The two types of power involved in the operation of a motor are known as working power and reactive power. Working power is the power required by the motor to perform its actual work, whereas the reactive power is needed by the motor to sustain in the magnetic field. "The contactors meant for power factor correction act as reactive power generators. They reduce the total amount of current drawn from the utility by providing reactive power. The contactor draws the current directly from the power line supply located near the load. It is remotely located from the distribution board and is fixed on a sub-distribution board, which will tend to limit the charging current," adds Sushmit. IEC and NEMA standards for motor To ensure flexibility in the motor operation and starting of motors, there are specific standards for motors from IEC (International Electrotechnical Commission) and NEMA (National Electrical Manufacturers Association). For the ease of operation, most motor contactors, starters, and relays are designed to meet these standards and UL standards. A NEMA specific controller is designed to meet the size specified in the NEMA standard, to provide electrical interchangeability. When inspection shows the need, the contacts can be replaced. These contactors are planned by the convention of sufficient reserve capacity. The IEC standards do not focus on the size ratings, rather signify that the contactor meets the requirements of many applications. Top vendors: Browse Related Reports:

About Technavio Technavio is a leading global technology research and advisory company. Their research and analysis focuses on emerging market trends and provides actionable insights to help businesses identify market opportunities and develop effective strategies to optimize their market positions. With over 500 specialized analysts, Technavio's report library consists of more than 10,000 reports and counting, covering 800 technologies, spanning across 50 countries. Their client base consists of enterprises of all sizes, including more than 100 Fortune 500 companies. This growing client base relies on Technavio's comprehensive coverage, extensive research, and actionable market insights to identify opportunities in existing and potential markets and assess their competitive positions within changing market scenarios. If you are interested in more information, please contact our media team at [email protected].

View source version on businesswire.com: http://www.businesswire.com/news/home/20171115005897/en/ |