|

While the available potential for wireless deployment in factory automation is high, the adoption of wireless is plagued by various concerns surrounding the wireless technology, one of which is lack of interoperability. In the recent past, interoperability was not as major concern as it is currently. People predominantly used to build their own systems or purchased them from a single supplier. Increasing plant automation has spurred the demand for wireless devices and systems for numerous applications like monitoring, alarm and telemetry with a large number of suppliers offering these systems or solutions. They are often customized on proprietary protocols but not based on a common standard or architecture. As a result, these devices offered from multiple suppliers are not often compatible with one another. So even though the options have increased, the end users have become more concerned about the compatibility of the devices.

End users are wary of becoming locked into a proprietary system that may hinder their future advancement, as they may not be able to adopt any new technology. Integration issues with existing infrastructure results in time and effort to be spent by end users, while they prefer plug-and-play devices. End users are also extremely cautious of investing in wireless when they are not confident about the benefits that wireless has to offer. Given that the end users will not be very keen to replace the existing fieldbus installation, suppliers should look to integrate wireless devices to existing wired fieldbus. Currently, plant IT network assumes significance over automation network. Hence, clear boundaries and smooth integration of wireless is required with the wireless devices existing network. The existence of several open and proprietary communication protocols results in confusion among the wireless devices end users who are ready to wait until a uniform standard is established.

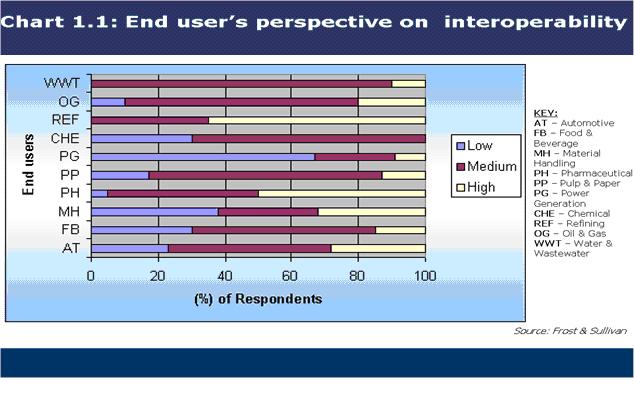

Around 83 percent of the end users across process and factory automation rated interoperability as a medium to high concern. However, the level of concern varies depending on different parameters such as end-user environment, types of wireless devices being used, the application area and the experiences of the end user with wireless devices. For example, the refining and pharmaceutical industries expressed a greater concern over interoperability among end users. They believed that integration with the existing network is important and the presence of numerous controls, fieldbus and automation devices implies that the wireless devices need to integrate seamlessly into the existing network. Similarly, in the oil and gas and the water and waste water industry wherein one of the preferred application areas for wireless devices is telemetry, end users were convinced that the wireless devices must be compatible with each other in order to ensure that there is a smooth flow of data.

Attainment of true interoperability would require an open architecture such as software based systems, in which various standards could be applied. Software such as National Instrument Laboratory Virtual Instrumentation Engineering Workbench (NILabVIEW) is capable of communicating with both standards-based and proprietary wireless networks. End users also believed that the lack of universal standard is another major concern. The need of the hour is to have common standards that offer interoperability from both the supplier and the end-user perspective.

In order to increase the level of adoption of wireless in the discrete and the process environment, suppliers must come up with wireless devices that are compatible with each other. Moreover, there is a need for a uniform standard and open architecture to enable the seamless integration of wireless devices with existing plant infrastructure such as fieldbus or other control systems. End users must also be convinced about interoperability through product trials or demos suppliers should offer. Nevertheless, the future for wireless devices in automation looks promising. Although the end-user concern is expected to hamper the adoption of wireless in the near future, the upcoming standards like SP100.11a and wireless HART are going to address this issue. In addition, numerous suppliers are supporting the initiatives that aim to establish a common standard. The increasing success stories of smooth wireless integration and functioning are likely to reduce end-user conservatism and raise the level of adoption of wireless devices.

Chart 1.1 indicates the different end user’s perspective on interoperability.

Syed Tauseef Ahmad is a Research Analyst Industrial Automation and Process Control - Europe at Frost & Sullivan (News - Alert). If you would like more information about this subject and related research please send an e-mail to Joanna Lewandowska - Corporate Communications, at [email protected] with the following information: full name, company name, title, telephone number, e-mail address, city, state and country. Requested information will be sent by email upon receipt of this information.

TMCnet publishes expert commentary on various telecommunications, IT, call center, CRM and other technology-related topics. Are you an expert in one of these fields, and interested in having your perspective published on a site that gets several million unique visitors each month? Get in touch.

Edited by Stefania Viscusi

|