What is Sheet Metal Fabrication?

Sheet metal fabrication is the process of using flat metal to build and assemble a variety of structures. The process of sheet-metal fabrication can play a role in the workflow of everyone ranging from mechanical engineers to professional welders. Since sheet metal is a malleable product available in varying degrees of thickness, it is versatile enough to use in all types of manufacturing. Sheet metal fabrication serves an essential production role in a host of industries, including ductwork, refrigeration, medical equipment, building facades, exhaust hoods, and modern art. Given the versatility of this metal, a look at the basic working techniques can provide insight on how this method might serve as an alternative to CNC machining for customized fabrications.

Bending Metal

Bending metal is a fabrication technique that incorporates hammering or press brake clamps.

- Form bending - This is the simplest and most straightforward bending method. With this method, a professional either bend the sheet metal over the edge of the desired shape or uses a hammer and shaping dolly until the right form begins to take shape.

- Press brakes - In this method, a fabricator places the workpiece between a matching punch and die, clamping it quickly into the desired shape using a flat metal bar. This method works well for angles as most press brakes can bend to around 90 degrees.

Cutting Metal

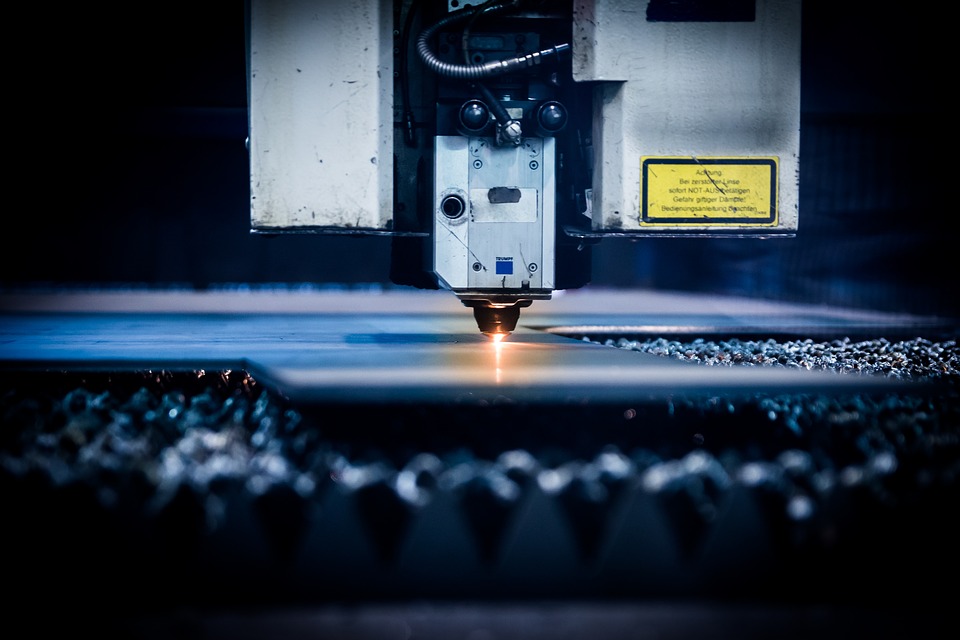

Cutting is the process of separating sheet metal by applying enough force to remove the desired shape from the rest of the material. It can involve shearing, sawing, chiseling, torching, or even laser-jet or water-cut cutting.

The most popular cutting methods include the following:

- Hand shears - This method uses a manual hand tool to cut material. Often referred to as "aviation snips," hand shears industry-standard tools found in most fabricator workshops.

- Power shears - Designed to slice through sheet metal quickly, power shears require less manual effort than hand shears. The two most common types of power shears are pneumatic shears and electric shears. Although great for cutting through large volumes quickly, power shears are not suitable for precise corners or more complex shapes.

- Throatless shears - These are specialized hand shears that cut straight lines, shapes, and radii with precision.

- Angle grinders - An electric handheld tool used to operate an attached disc that grinds or cuts through sheet metal.

- Plasma Cutters - An innovative tool that uses the fourth state of matter (plasma) to cut lines with extreme accuracy.

Shrinking Metal

This method alters sheet metal into custom shapes. There are three subcategories:

- Tucking - This time-tested method bunches the metal using a hammer and form tool.

- Shrinker - The shrinker uses textured jaws to grasp and tightly compress sheet metal into the desired shape.

- Heat shrinking - This specialized method requires a trained worker to heat overstretched metal with a torch so that it shrinks as it cools.

Stretching Metal

Stretching is a method of pull-forming metal into nearly any complex shape. There are three popular methods:

- Hammer and dolly - With this method, the fabricator holds an object behind the sheet metal. The fabricator then hammers the opposite side to stretch the metal into shape.

- Stretcher - A mechanical tool that allows the fabricator to stretch metal using a level or foot pedal.

- English wheel - This machine stretches material using a top wheel and a complementary bottom-anvil wheel.

Applications

Fabricated metal is used in many ways. Copper sheet metal for sale can be used in many applications including creating brass or phosphor bronze.

- Motor vehicle industry: Vehicles are made of many materials, but the main material is metal. For instance, the chassis is aluminum, and without metal, vehicles would not have proper structural integrity. About 7% of copper sheet metal for sale is used in the motor industry.

- Tools: Almost everything we use in our daily lives would not exist without metal. Nail drills, vehicles, spades, saws and many more are as a result of metal fabrication.

- Laptop and smartphone shells: Phones and computers are as a result of metal fabrication. The sleek laptop and smartphone cases are made of metal.

- Kitchenware: Almost everything in the kitchen is made of metal.

- Aerospace: Many aircraft components are made of metal. Designing an aircraft is not a simple task, and one cannot compromise structural integrity. The components must withstand a wide range of temperatures, high pressures, and chemical exposure.