As our technology use has evolved, so has the industry of machining. Today consumers can purchase a self-parking vehicle and buy drones for their leisure. All those neat gadgets are only possible through a manufacturing ecosystem that supplies machined parts. Perhaps it's time we shift away from calling the machining industry a trade and start recognizing it for what it has become: a technology field. And as technology continues to evolve, a career in machining is filled with endless possibilities.

The future of machining is becoming much brighter. With the demands of technology, more people are entering the field, and the manufacturing industry will flourish. The jobs created are proving to be well-paying and ever-changing.

What is a Trade Job?

A trade job generally refers to any job with duties requiring advanced training and skills gained through means other than a bachelor's degree. Usually, a person learns a set of skills through on-the-job training or a vocational school training program. Some examples of physical labor trade jobs include construction workers, plumbers, or electricians. Other trade jobs require manual work like pilots or dental technicians.

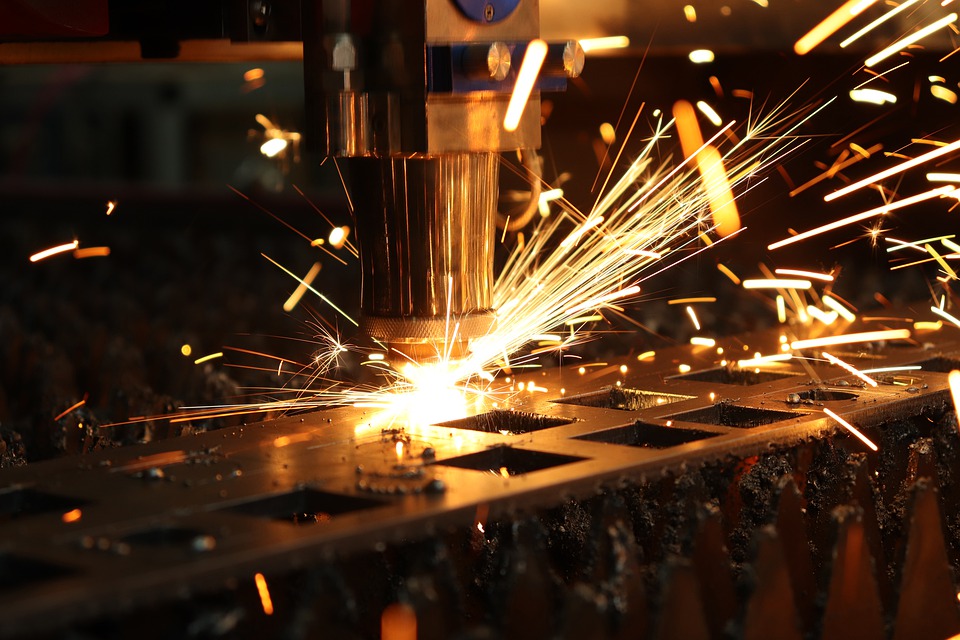

For some time, the machining industry has been rapidly expanding in scientific knowledge. Machining is now an essential link in the supply chain to transform any technological idea into a physical product. The trade of machining isn't merely the cutting of metals. While cutting metals is still an important part, there is a lot of science and technology behind it.

The field of machining now uses advanced materials, tooling, and equipment to make components. A notable example is in the dental area. A skilled machinist can take implants and create five-axis tool paths or models through sophisticated scanning and advanced computers. This shows just how the machinist trade requires less physical labor and more specialized knowledge of technology.

Technology Replacing Labor Demands

With the continued evolution of technology, many products and production processes have changed the demand for labor. With automation, technology has replaced some workers on the physical assembly lines with computers and robots. However, jobs haven't been lost. The labor has only been reallocated. Instead of physical labor, these technological shifts call for skilled workers to manufacture high-quality parts to make automatic work. Therefore, today's machinist isn't just one peg on the assembly line. Today's machinist has many more skills, like a computer programmer, a process improver, a quality control technician, and much more.

Computers in the workplace have been the central force driving changes in skilled workers' wages relative to the wages of unskilled workers. There is a relatively lower demand for workers performing routine activities and a higher demand for skilled workers. However, technological progress doesn't always eradicate physical labor and its operators. Sometimes, computers and software assist workers. Computer numerical control, also commonly referred to as CNC machining, is one example that is gaining popularity.

How Does CNC Machining Work?

Through computers, CNC machining automates controls of machining tools: drills, mills, and 3D printers. A CNC machine processes a piece of metal, plastic, wood, or any material component by following coded program instructions. A machinist doesn't manually control the machining operation as operators do with hand wheels or levers.

Instead, the machinist must provide the computer with specific input instructions to deliver to a CNC machine using a particular software. The instructions are transformed by "post processor" software into the commands necessary for a particular machine to produce the component and are then loaded into the CNC machine.

An effective CNC machining service has to be precise and affordable without sacrificing quality. CNC machining services include gear hobbing, electrical discharge machining, CNC turning, and CNC milling. Each is a careful, thoughtful process illustrated best by Fictiv's digital manufacturing ecosystem.

For example, when one company wanted to create the first smart wireless door for businesses, it needed a machining service that could transform their vision into an actual prototype. The company's smart wireless door would replace all keys, keycards, and fobs. In its place, the company would construct a smart door that is enabled with precision hardware and paired with a simple smart-device-driven application.

To accomplish this goal, Fictiv worked on a wide range of technologies to manufacture the requested prototype. During the initial quoting process, technical application engineers can provide expert guidance on the design's manufacturability to ensure the parts received meet the company's requirements. Some expert machinists use advanced technology to cut specific metals according to specifications. Then, supplier quality engineers perform quality assurance. Each step is an essential link in the chain to manufacture a successful end product; in this case, a smart door.

The Future of Machining

The upcoming wave of technological advances, such as artificial intelligence and robotics, will likely continue to disrupt the world of machining. Technology will make some skills obsolete, while enhancing others and creating new ones. Most people who think of machining as a trade miss the importance of the technological ecosystem. Machinists are an essential component in the success of every technological advancement. As technology progresses, the field of machining will continue to demand more technically-skilled operators.

Oregon State University knows firsthand the importance of the machining industry to the future. OSU seeks to encourage our youth to develop the skills required to enter the modern machining field. Becoming a machinist is the technology career of the future. Visit the OSU MIME Machining and Product Realization Lab to learn more.