Since the inception of robots in 1961, the development of industrial robots has accelerated. Contrary to before, when robots were mainly used in the automotive industry, today, we see other fields such as food, electrical and electronic, medical enterprises embracing the application of robots in their workplace.

Some robots are being programmed to perform tasks such as; painting, assembling, welding, palletizing, and material handling. Although robots are widely used in different fields, one may think that there are many kinds of robots, however, industrial robots are generally categorized into six major types.

In this article, we are going to look at the six different types of industrial robots, depending on their size, industry, and functions.

Articulated Robots

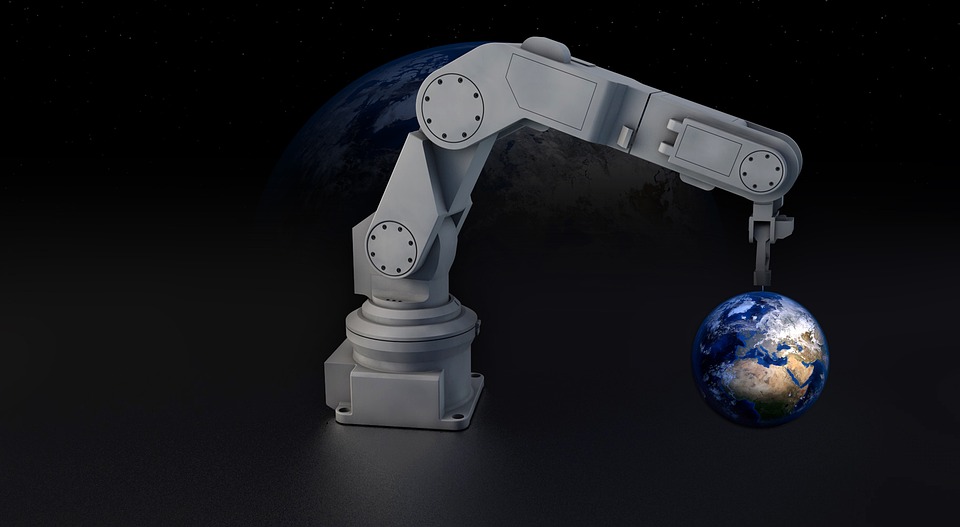

Articulated robots are the most common type of industrial robots today. The design of this robot imitates a mechanical structure that is similar to the human arm. The rotary joints in this robot can range from two to ten. Some can have even more than ten joints.

The robot’s arm is usually connected to the base via a twisting joint. Although this type of industrial robot features a high degree of freedom, controlling it can be rather tricky. The joints in this robot are also referred to as an axis, and they are the ones that provide an additional range of motion to the robot.

The articulated robots are used for different jobs, such as welding in the car industry.

Cartesian Coordinate Robots

Also known as a gantry or rectilinear robot. The cartesian robot usually performs its movements by sliding on three vertical axes. Although they may have an attached joint to perform rotational movements, most of the gantry robots use three linear joints (X, Y, Z) to coordinate their motion.

Although this type of robot usually requires a large area for its installation, it offers high precision levels and is relatively easy to use. This type of robot Is often used in the transportation of heavy items.

Cylindrical Robots

The cylindrical robot usually has at least one prismatic joint and one rotating joint at the base, to connect the links. While the prismatic joint moves in a straight motion, the rotating joint usually uses a rotational movement along the joint axis.

Although the cylindrical robot is among the early industrial robots, it is still being used today to convey items such as LCD sheets.

Spherical Robots

Also known as polar robots, these robots usually feature a central pivoting shaft with an extendable arm. The arm of this robot is usually connected to the base with a twisting joint. It also has a combination of two rotating joints and a linear joint.

Just like the cylindrical robots, the polar robots were also widely used in the initial days of industrial robot advancement.

SCARA Robots

SCARA is an abbreviation that stands for 'selective compliance assembly robot arm.' This type of robot is mainly used in assembly and handling applications. It specializes in lateral movements. Since all its rotating shafts are usually vertically positioned, the effector that is typically attached at the end of its limb moves horizontally only.

This robot's performance involves the arm's movement towards a point on a flat surface in high-speed motions, and then raising and dropping the effector. As such, these robots are more useful for level surface operations.

Delta Robots

The delta robot is also known as the parallel link robot. This type of robot usually has parallel joints that link it to the base. The spider-like robot controls the positioning of the effector through the use of its three arms.

Since each joint usually has direct control over the effector, this robot can achieve high-speed operations. It is often used in applications such as selecting and sorting food products.

Conclusion

Although the above-discussed robots are all classified as industrial robots, it is essential to note that each robot is different from the other in terms of accuracy, speed, and work range.

Understanding each robot's overall mechanical structure can assist you in making an informed choice depending on your needs and preference.